What Protects Devices from Electronic Interference?

Summary: Devices exposed to interference wouldn’t work, but shielding protects them.

There is a reason why you’re not supposed to use electronics like a cell phone in sensitive areas like a hospital. While you’re likely to see fewer signs posted about cell phone usage in these areas today, this was a major problem just a few years ago. The usage of electronics can interfere with other electronics, unless shielding is used to protect the internals.

How Shielding Works

Most electronic devices have some kind of shielding in place to protect the internals. Cell phones might have a metal plate installed, which was manufactured with a special sputter coater to metalize the plate. This shielding blocks electromagnetic interference produced by the device, and existing around the device.

Shielding is produced at different sizes and shapes, mostly to fit the device being used. UHV sputter deposition is also used, especially when only a thin film of metallic ink is required. Sometimes, devices are coated in these thin films to reduce weight, costs or other aspects of production.

One of the medical device coatings most beneficial to patient health is also one of the most commonly overlooked. The metallic coatings that line all of the electronic monitors in a patient’s hospital room could easily short without this shielding.

Manufacture

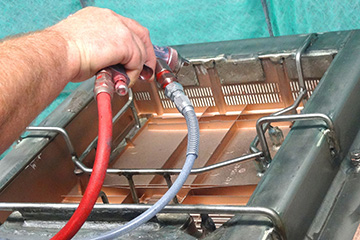

Engineers discovered that they could use materials from one element to change the properties of another. A magnetron sputtering system is frequently used to add a treatment of thin-film copper or nickel, which would otherwise be impossible using manual means. The precision temperature required is difficult enough, but a uniform coating is required. If there are any defects, the device may not function as intended.

Bio: Denton Vacuum, LLC has been producing thin-film deposition systems and sputter coaters for more than 50 years, making the company one of the most trusted names in advanced manufacturing.